-

Ten common traps

Ten common traps in designing a cleanroom. Avoid these pitfalls, when working with cleanroom design team. Get It Now

Who are we?

We are experts in cleanroom design,manufacturing,and installation since 1990, working alongside companies across all industries. We have set the standard for quality. Alongside our expert eye for detail at every stage of construction the most compelling reason to engage us would be each cleanroom we have commissioned over the last 25 years was fully compliant and operational from the first day.

Find out what Nature Care, Pharmatel Fresenius Kabi, Blackmores, Australian Defence Department, Sphere Healthcare, Select Foods, IVF Australia, Sydney University and many others already know. Cleanrooms Australia offer the best design solutions for cleanrooms, modular cleanrooms and passthrough hatches. For allyour cleanroom needs call us on 02 9939 1040 today!

Step over benches

The Cleanrooms Australia range of step over benches are constructed in the same simple, sturdy and efficient designs as our other ranges…

Air Showers

These specialised antechamber systems are designed for use at the entrance to the cleanroom facility, and they ensure cleanliness of personnel and support classification requirements for the facility.

Portable Cleanrooms

Special-built, GMP & ISO compliant, internally or externally relocatable air handling units for a cleanroom that retains your asset and supports your business’s growth and expandability.

Pass through hatches

Our pass through hatches are available in a wide range of models and, because they are manufactured locally, any size variation can be accommodated…

We were impressed with Cleanrooms Australia’s can do attitude, flexibility with budget, design constraints and ultimately a very professionally built cleanroom.

We are very happy with the cleanroom, the construction and the quality. It works for us and does what we need.

In all our dealings over the period of 8 years we have found Cleanrooms Australia to act with integrity & to be caring,trustworthy and reliable contracting and maintenance business, with a conscientious view to going the extra mile.

We built our own room in Melbourne, what a mistake, we aren’t interested in doing that again, our best advise is to leave the design and construction (and the headaches) up to the professionals.

You made our unreliable cleanroom a resource instead of a liability. The most impressive thing about cleanrooms was your staff.

I enjoyed working with Cleanrooms Australia from design through to the actual installation and back unto upgrades and the continuation of services. I was impressed fundamentally by your ability to design and deliver.

Cleanroom Australia’s service calls were professional jobs, all done promptly and in a timely manner at fair price. S. B.

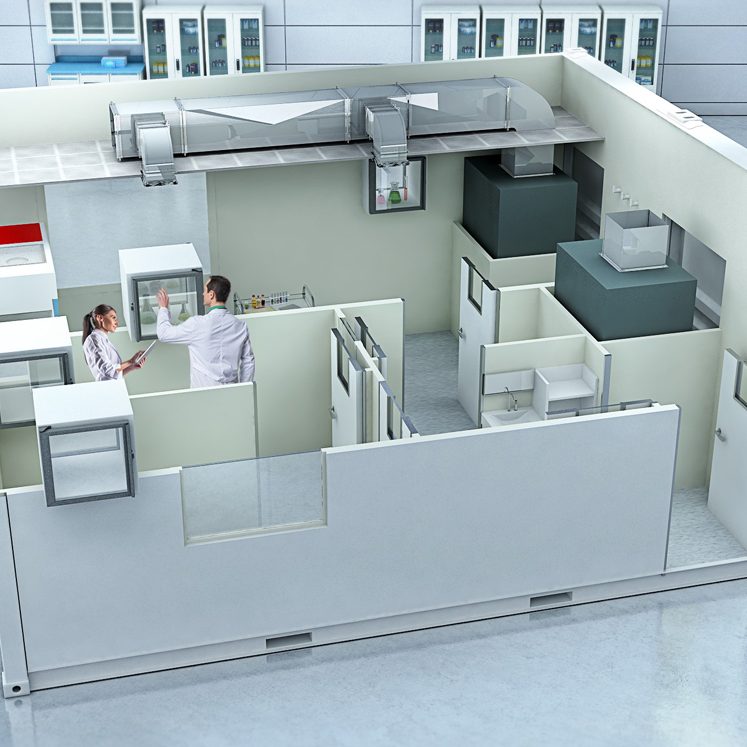

Our Latest Project

SA Defence

South Australia Defence approached Cleanrooms Australia to design and build a cleanroom facility they could use to service and test valves that play a vital role in the hydraulic trolley system used to service ships for the Australian Defence Force.

- The cleanroom had to be ISO 14644 Class 8 compliant and contained within a 20-foot shipping container.

- The cleanroom also needed to be delivered to the dry dock facility and landed on the warehouse floor in South Australia.

- The cleanroom was successfully delivered and installed in the client’s South Australian warehouse facility and is currently in effective operation.

Who we work with