These specialised antechamber systems are designed for use at the entrance to the cleanroom facility, and they assist with cleanliness of personnel and support classification requirements for the facility. By producing high velocity clean air streams, cleanroom air showers dislodge and carry away a quantity of large dust and dirt particles from the garments of any personnel entering the facility.

These specialised antechamber systems are designed for use at the entrance to the cleanroom facility, and they assist with cleanliness of personnel and support classification requirements for the facility. By producing high velocity clean air streams, cleanroom air showers dislodge and carry away a quantity of large dust and dirt particles from the garments of any personnel entering the facility.

Highlighting the importance of air showers for cleanrooms

These hygiene instruments are highly crucial as they individually assist the environmental conditions of the cleanroom or cleanroom suite to be supported. The minimisation of large particle contamination, being carried in on technicians’ garments, that can have fatal results on equipment or products within the facility. For this reason, air showers have become common place for many industries where technicians are moving from a dirty classification room to high classes of cleanrooms without re-gowning, such as in science, research and manufacturing fields. Constructed from the highest quality materials in Australia, our products have been designed with operational experience in mind to ensure best practices are employed each and every time.

Finding the best air shower system for your requirements

Finding the best air shower system for your requirements

Systems vary due to many existing designs. Existing cleanroom showers can be retrofitted to suit an existing facility and as such can be placed directly on the ground and turned on. Designs feature single-side, double-side, and three-side showers, where stainless steel nozzles produce high velocity direction-adjustable clean air stream and are often complemented by HEPA filters to specifically target particles that are larger than 0.3 micrometres. No matter whether your industry is in biomedical research and life science or pharmaceutical and parenteral drug production, we can deliver an air shower system to assist your reduction of technician or inward goods particle carry-over conditions for most environments. For other essential cleanroom products including laboratory pass-through hatches and air handling units, search our products section.

Hurricane Air Shower

Stand alone airshower unit to be installed in situ at your facility.

Stand alone airshower unit to be installed in situ at your facility.

- Electro-magnetically interlocking doors

- Doors lock during cycle

- Self closing doors to ensure door closed and sealed

- Doors easy to open for single hand operation

- Doors with full glass to provide visual line of sight to second door to allow use as airlock as well as airshower

- Easy to clean and maintain

- High Capacity HEPA filtered air system containing contaminants

- Return Air Filters to clean air system of contaminants

- High-velocity streams created to cause flapping, thus scrubbing occupant

- of particulates

- Air flow reaches max of 38 mps (85 mph)

- Limit risk of cross contamination of particle debris between environments

- Air nozzles are adjustable to fine tune efficiency of program op

Airshower Specifications

| Overall Dimensions | 1430 mm Width x 1110 mm Depth x 2900mm Height |

|---|---|

| Internal ceiling height | 2400 mm |

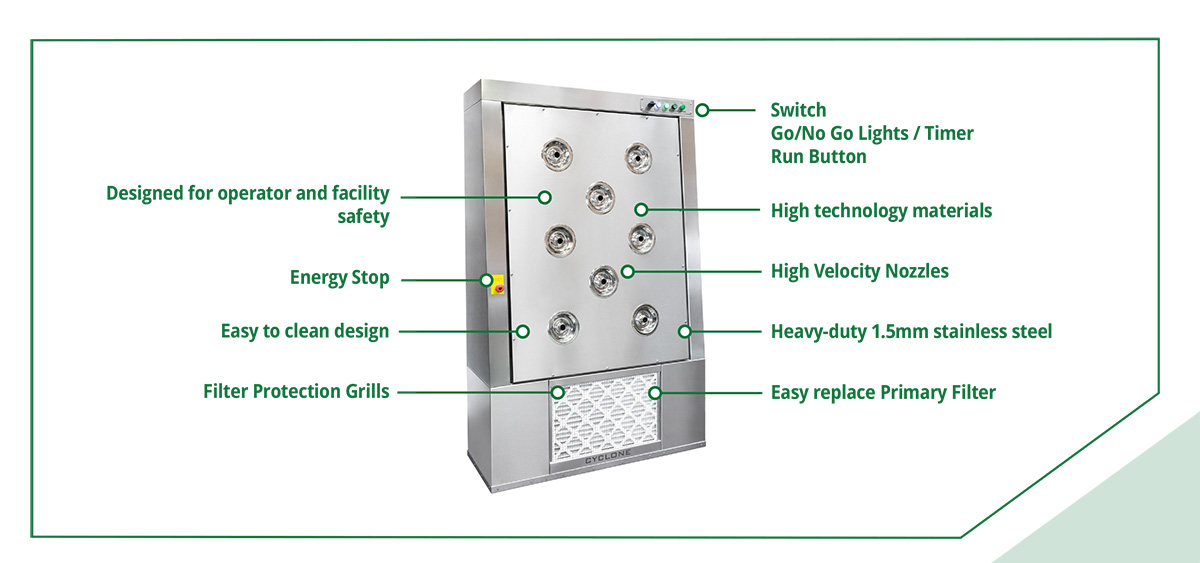

Cyclone Air Shower

Single or multiple units plugged into existing airlock.

- Economic and easy to operation solution to convert existing space into functional airshower

- Simply plug into wall and use

- Limit risk of cross contamination of particle debris between environments

- Stainless steel for easy cleaning and long life

- East to clean and maintain

- Air flow reaches a category 1 Cyclone strength winds to dislodge particles

- High velocity nozzles sufficient to remove debris from cleanroom garments

- High-velocity streams created to cause flapping, thus scrubbing occupant of particulates

- Nozzles are adjustable to tailor air flow to suit need and space

- Primary and secondary filters work together to scrub the interlock of course and fine particulates

- Easy removable protection Grille

- One handed Filter replacement

Airshower dimensions: 1200 mm Width x 450 mm Depth x 1900 mm Height

Portable stand alone or in tandem for tailor made solution

- Multiple units can be chained together to suit needs and space

- Single plug in to power point, rest of chain supplied by main unit

- Multi Options 1 / 2/ 4/ 6/ 8 units in tandem

- Flexibility of placement